Increased accuracy, smoother fastening

Improved drivetrain design prevents from center run-out and reduces damage to screws even with high speed fastening of long screws.

1: Hammer

With optimal tuning of the compression spring and intelligent motor, the EY75A7 avoids ineffective impacting, reducing damage to the screw as well as noise and vibration.

2: Improved bearing design

New bearing design on the driveshaft greatly reduces ‘center run-out’, improving accuracy and allowing smoother driving. Amplitude of vibration: 1.4mm* with 110mm long screw. *Internal test result

3: Smooth Speed Control

Improvements to the tuning of control electronics in the switch enable smoother operation during light or heavy use.

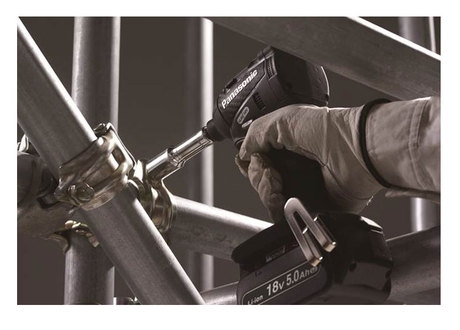

Robust build for heavy-duty use

Battery capacity in M12 high-tensile bolt: more than 30.000 pcs *1

“Powerful and Compact “New Brushless Motor

Approx. 200%*2 more life cycles, thanks to new brushless motor development. Also, thicker motor shaft (φ5mm) ensures more strength for heavy-duty use.

Increased housing durability

To increase housing durability, metal plates have been added where the battery locks into the tool. This helps prevent wear and damage caused by abrasion and vibration during heavy use.

Fresh new ‘CARBON’ design

To enhance the internal engineering and technology developments, a fresh new body design and material finish has been developed. With the unique carbon fiber textured finish and new comfort grip, style is added to substance with improved ergonomics too.

English

English Latviešu

Latviešu Русский

Русский